However, the objective and point of application are different.

When it comes to making holes in any surface or workpiece, the process is either referred to as centering, turning, boring, reaming or honing. Ultimately, the type of machines and the processes required will depend on the hole diameter, finish, and tolerance level requirement. What is the principle of boring?Ī variety of different machinery and machining processes are required in order to make holes on solid surfaces. However, there’s a method and a process to it which you will need to get right so you can get the desired results. You may need as much as 200 hp in order to conduct certainĪlthough boring does come with its own set of tools that are perfectly suited to the task at hand, if you do not have any of these boring tools available, then it is possible to use drills for boring. Workpieces usually require horizontal boring mills.

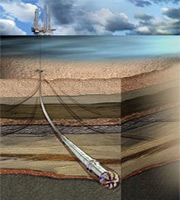

These machines are available in different sizes and styles.īoring tasks on small workpieces can be carried out on a lathe while larger Machines that are specifically designed to focus or assist in boring workpieces as its primary function are boring mills and other boring machines. You can use universal machines, general-purpose machines, milling machines, and lathes. Based on the parameter values, as well as the requirements of a certain application, you pick the process that you want.ĭifferent types of machinery or tools can be used in order to facilitate a boring process. Turning and boring have abrasive counterparts when it comes to internal and external cylindrical grinding. The first boring machine was created in 1775 by John Wilkinson. The boring process itself is performed using a lathe, milling machine, or a horizontal boring mill.Įach machine makes use of a different mechanism however, each one is designed to make an existing hole larger, and that’s the defining characteristic or difference between boring and drilling. So from what we can see so far, drilling creates a new hole in a workpiece while boring simply enlargens an existing hole. So as you can see, this is a big contrast to drilling, which is basically performed to create an initial hole in a workpiece.

When we speak of boring, we are referring to a cutting process that involves the use of the single-point cutting tool, otherwise known as a boring head to make an existing hole in the workpiece larger.

0 kommentar(er)

0 kommentar(er)